Message

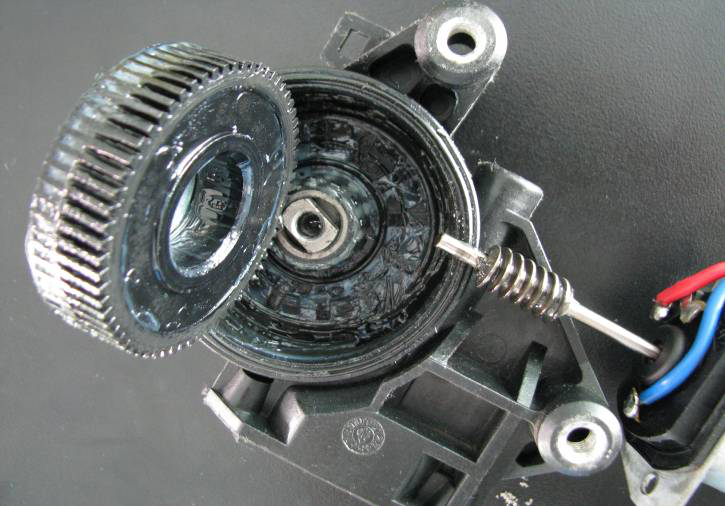

Basic structure and lubricated parts of automobile glass lifter

1. The car glass lifter is divided into: fork arm type, rope wheel type and flexible shaft type according to the transmission mode;

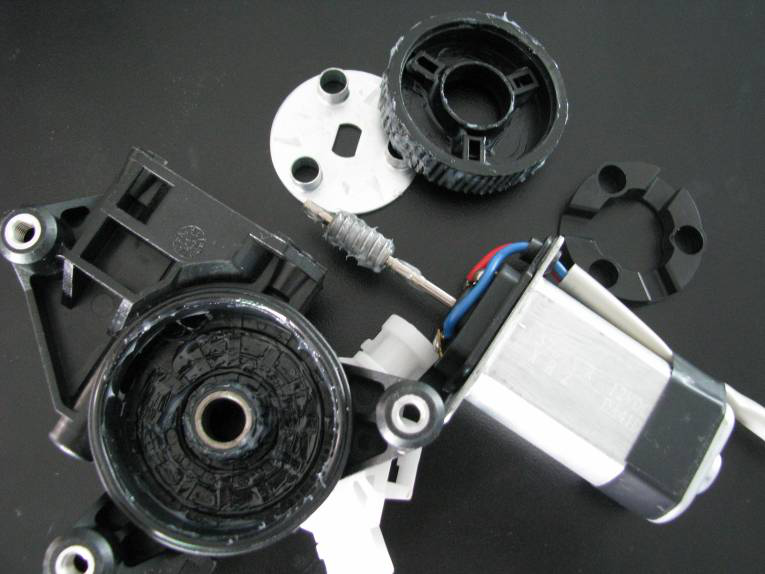

2. The components of automobile electric glass lifter: glass lifter motor, mechanical lifting mechanism and control system.

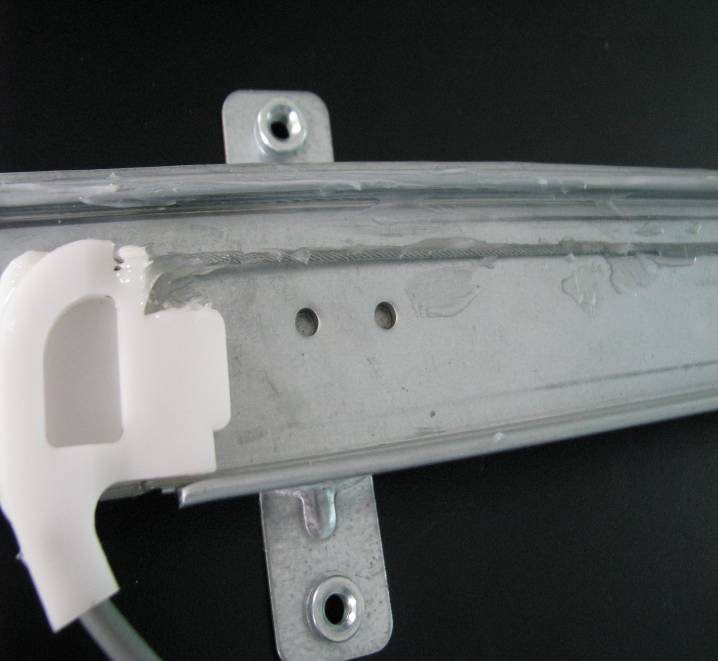

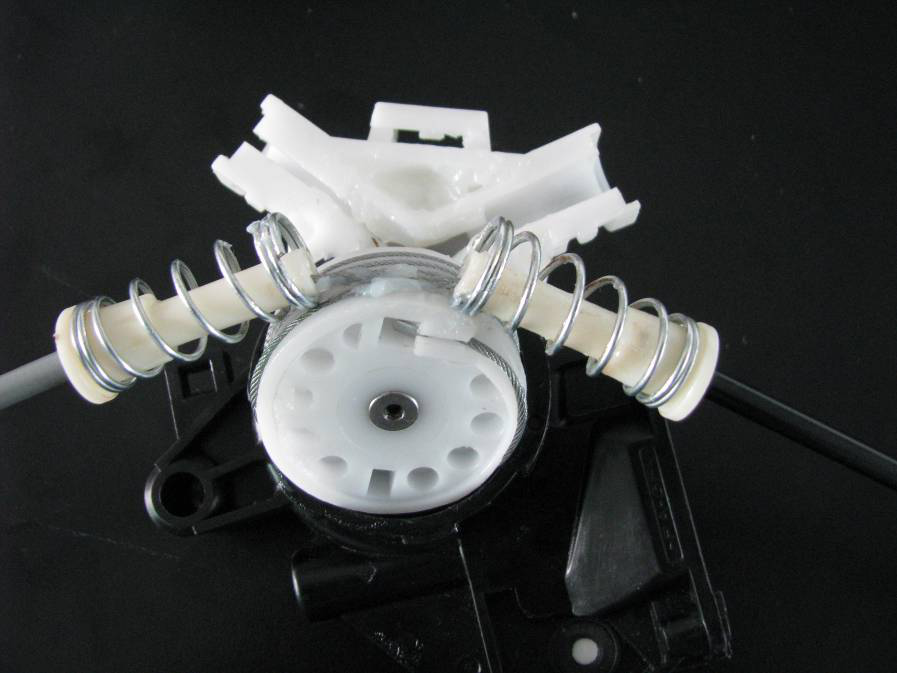

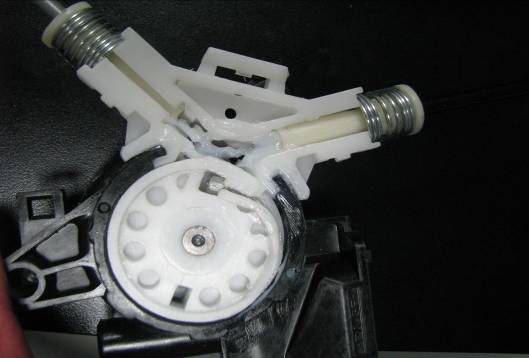

The rope wheel type electric glass lifter is composed of a glass lifter motor, a steel wire rope, a guide plate, a glass mounting bracket, etc.

3. Working principle of automobile electric glass lifter: start the motor, drive the reducer to output power, pull the wire rope to move the glass mounting bracket, and force the door and window glass to move up or down linearly.

4. Lubrication point of automobile electric glass lifter:

A Fork-type electric glass lifter lubrication point

B Lubricating point of rope wheel type electric glass lifter

Some failures of the glass lifter

Serial number | Fault phenomenon | cause of issue | Troubleshooting |

1 | The glass cannot lift | The cause of the motor itself (poor brush contact, etc.) | Replace the motor |

2 | Worm gear stuck and ablated | Replace the motor | |

3 | Broken wire rope (cause of the wire itself) | Replace lifter | |

4 | Stent deformed badly | Replace the bracket | |

5 | The gear fan is seriously worn (poor lubrication) | Change the bracket or change the grease | |

6 | Glass ups and downs | The guide rail is severely corroded, stuck or blocked by glass (poor lubrication or foreign objects) | Change the bracket or change the grease |

7 | Worm gear worm slip and tooth jumping (poor lubrication) | Replace the motor or change the grease | |

8 | Abnormal sound of glass lifting

| The reason of the motor itself (the motor shaft gap is large, etc.) | Replace the motor |

9 | Worm gear dry grinding (poor lubrication) | Replace the motor or change the grease | |

10 | Dry friction between wire rope and guide plate (poor lubrication) | Replace the motor or change the grease | |

11 | Dry friction of wire rope (poor lubrication) | Replace the motor or change the grease |

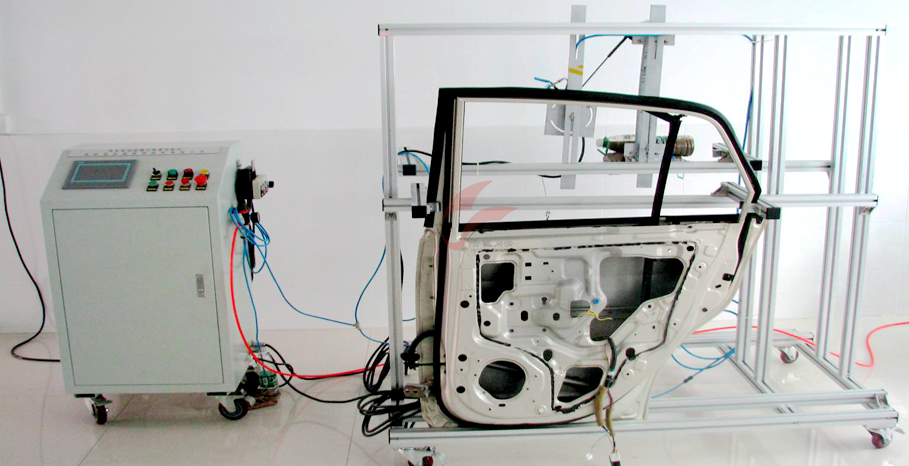

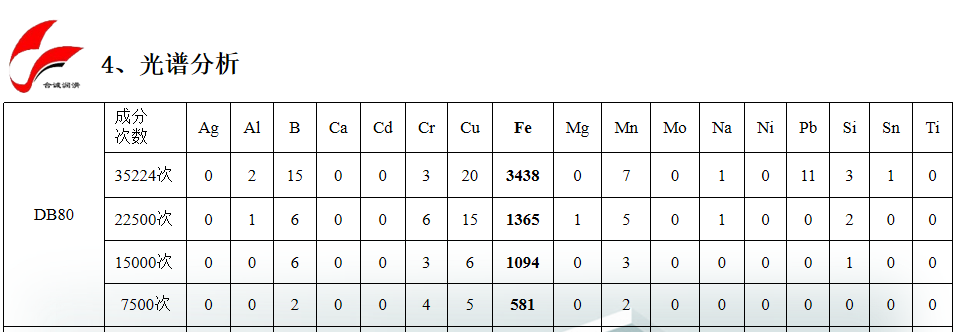

Hecheng Company's Lubricating Solution for Automobile Glass Lifter: Bench Test Simulates Automobile Glass Lifter

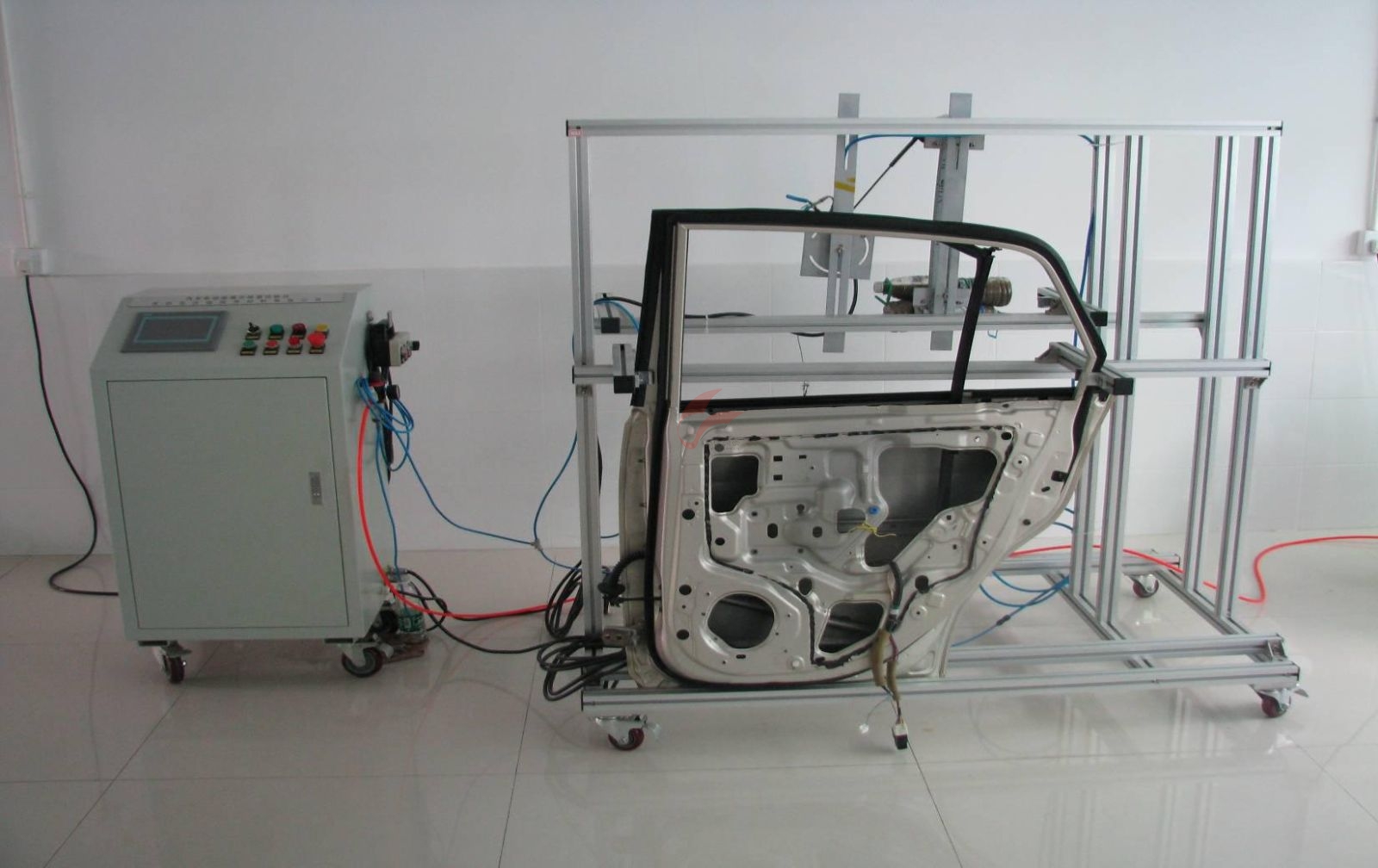

Introduction of experimental bench

1. The test bench of electric glass lifter for automobiles is mainly composed of: electric control console and operation station;

2. The test bench has two stations, which can simulate the endurance test of the fork arm type, rope wheel type and flexible shaft type glass lifter;

3. The tst stand can monitor the starting current, blocking current and endurance times when the glass rises and falls, so as to judge the endurance life of the glass lifter.

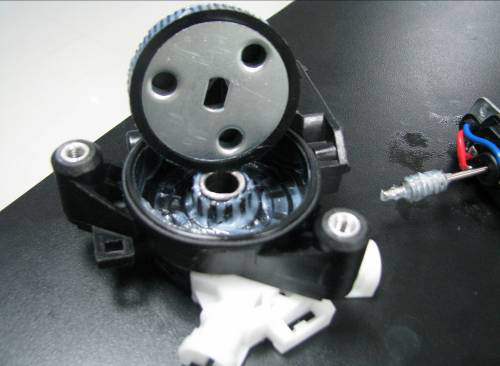

1. Select the rope wheel type electric glass lifter and use petroleum ether to clean the worm wheel, wire rope and guide plate of the motor reduction mechanism;

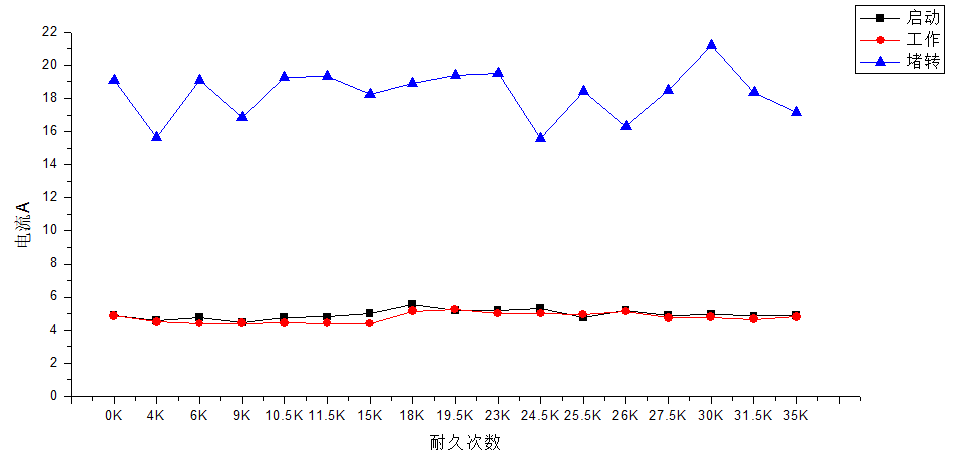

2. Add different grease to the worm gear, wire rope and guide plate;

3. The sampling rules of current value are as follows: each rise and fall 1000-2000 times is a cycle, sampling is performed, and the current values of 10 groups of opening and closing cycles are measured each time, including the starting current and the blocking current of the rise and fall. This repetition continues until the malfunction stops working or the expected endurance life is reached.

1. The worm gear reduction mechanism of electric glass lifter needs to be lubricated.

2. The mechanical lifting mechanism (gear fan, wire rope) needs to be lubricated.

Grease for worm gear of electric glass lifter has the following requirements:

※Excellent high and low temperature resistance, applicable temperature range: -40 ~ 80 ℃, low temperature starting and running torque is extremely small;

※Low friction coefficient, good lubricity and adhesion, can reduce running noise for a long time;

※Outstanding water resistance and corrosion protection;

※Good compatibility with most plastics and elastomers;

※Excellent oxidation stability, mechanical stability, colloidal stability and anti-aging ability, extremely long service life.

The main technical parameters of the electric glass lifter are nominal voltage, working voltage, rated load, glass stroke, glass rise time, maximum current consumption of the motor, braking force and life, etc. In addition, it must be able to withstand environmental tests such as high temperature, low temperature, salt spray, dust, water spray, vibration and impact, and the product should be able to withstand tests such as motor braking, motor overcurrent protection, electromagnetic compatibility, noise and life. .

Please fill in your message, we will reply as soon as possible!