Technology R & D

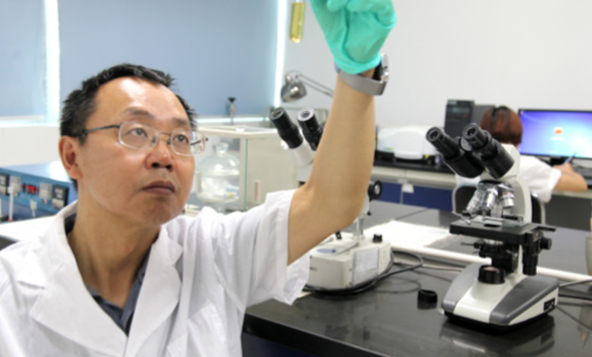

With more than 40 years of experience in the industry, senior veteran engineers, internationally renowned expert consultants, and a team of young engineers with rich industry experience, combined with mature technology and new technology, create a world-class lubricating grease.

The company has strong R&D strength, has many industry experts and a group of experienced grease technical backbone, and a group of excellent employees with skilled production technology. The establishment of partnerships with higher scientific research institutions such as Sun Yat-sen University and South China University of Technology makes the company's scientific research and innovation strength even stronger.

Please fill in your message, we will reply as soon as possible!