Message

The main lubrication problems of toy plastic gears:

※, The noise is large, and the noise reduction effect of the grease during the gear rotation is not good;

※, continuous noise reduction, the noise increases after the gear runs for a period of time;

※, small current, the consistency and viscosity of the grease are not suitable, causing the current to increase or even crash;

※, the speed is fast, the grease originally attached to the surface of the gear is thrown away, and the adhesion is not good;

※, Strict long-life lubrication requirements, the lubricating grease on the gear evaporates too fast, the gear dries for a period of time, and the lubrication is not enough;

※, It is incompatible with plastics and produces tooth burst;

※, strict environmental protection requirements, many oils and fats have not passed the relevant environmental certification;

Solution:

※ For noise problems, choose a grease with a suitable consistency and a slightly higher viscosity to improve noise reduction performance;

※ For the continuous lubrication of gears, select a grease with good mechanical stability;

※ Considering the current problem, the grease should not be too thick;

※, the gear speed is fast, select the grease with good adhesion;

※ For lubricating greases that will dry out after a period of time, you need to choose high-precision base oils and precise processes to blend lubricating greases. You cannot choose products made of ordinary mineral oils;

※, using grease with good plastic compatibility;

※ In response to the requirements of the current market, all toy products must meet environmental protection requirements.

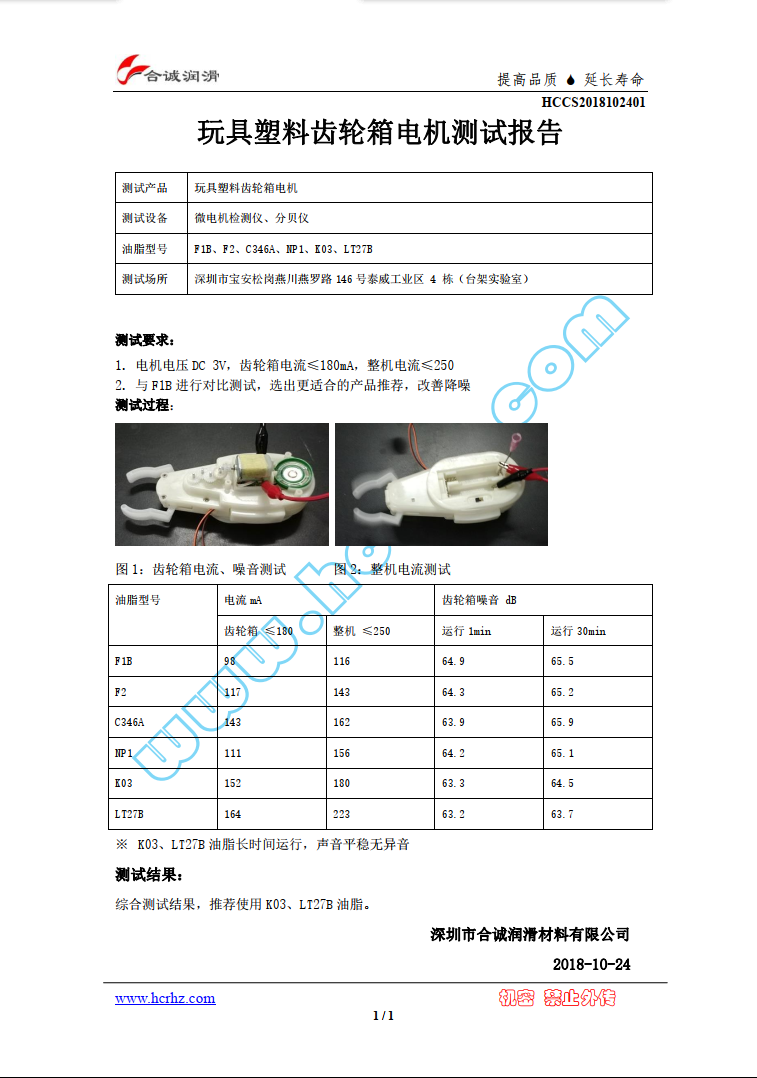

Bench test:

Please fill in your message, we will reply as soon as possible!